Helix® Heavy Lift Slings

Helix high performance fiber roundslings are narrow width heavy lift slings designed to fit in lifting hardware with limited space. Helix lifting slings utilizes K-Spec® core fiber, the strongest and most trusted roundsling core yarn on the market. Refined over 30 years, K-Spec is extremely durable, strong, light weight, and has less than 1% elongation at rated capacity. Helix slings offer high strength capacities while maintaining a narrow profile. This makes Helix the ideal solution when lifting with narrow hardware or limited space. Helix is equipped with an abrasion and chemical resistant HMPE braided jacket that protects the load bearing core yarn. This jacket is braided in the USA. Rifled Cover Technology is braided directly into the HMPE Helix Jacket increasing strength by 17% while reducing sling weight and width.

Helix Sling Design

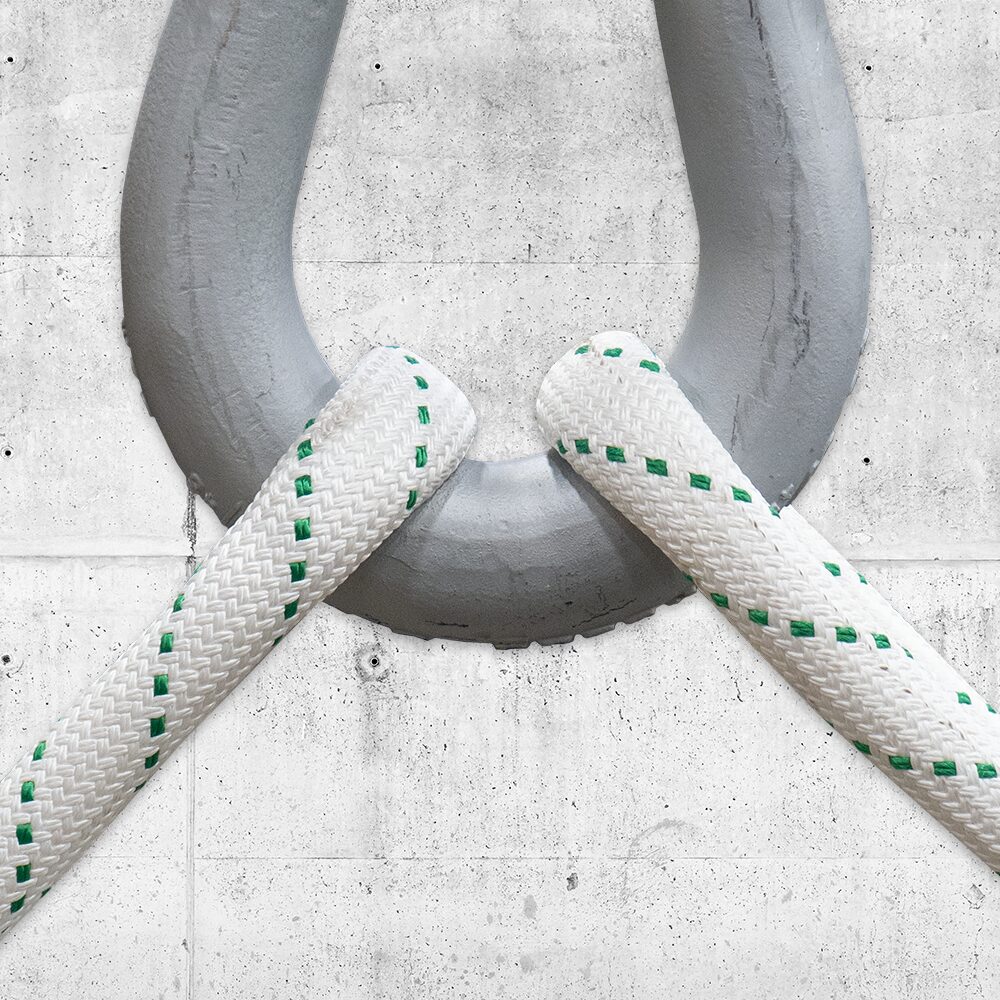

Introducing the Helix Roundsling, a high-performance, endless roundsling designed to provide exceptional strength and durability with a very narrow sling width footprint for demanding lifting applications. This advanced roundsling features a braided HMPE jacket, offering excellent abrasion resistance and protection for the internal load bearing core, which is made from high-performance K-Spec fibers. Crafted with precision on the Slingmax Roundsling machine, by Slingmax Dealers, the Helix Roundsling ensures consistent quality and reliability, making it the ideal choice for heavy lifts when narrow hardware or trunnions are a factor in the lift plan.

Advantages of Helix Slings

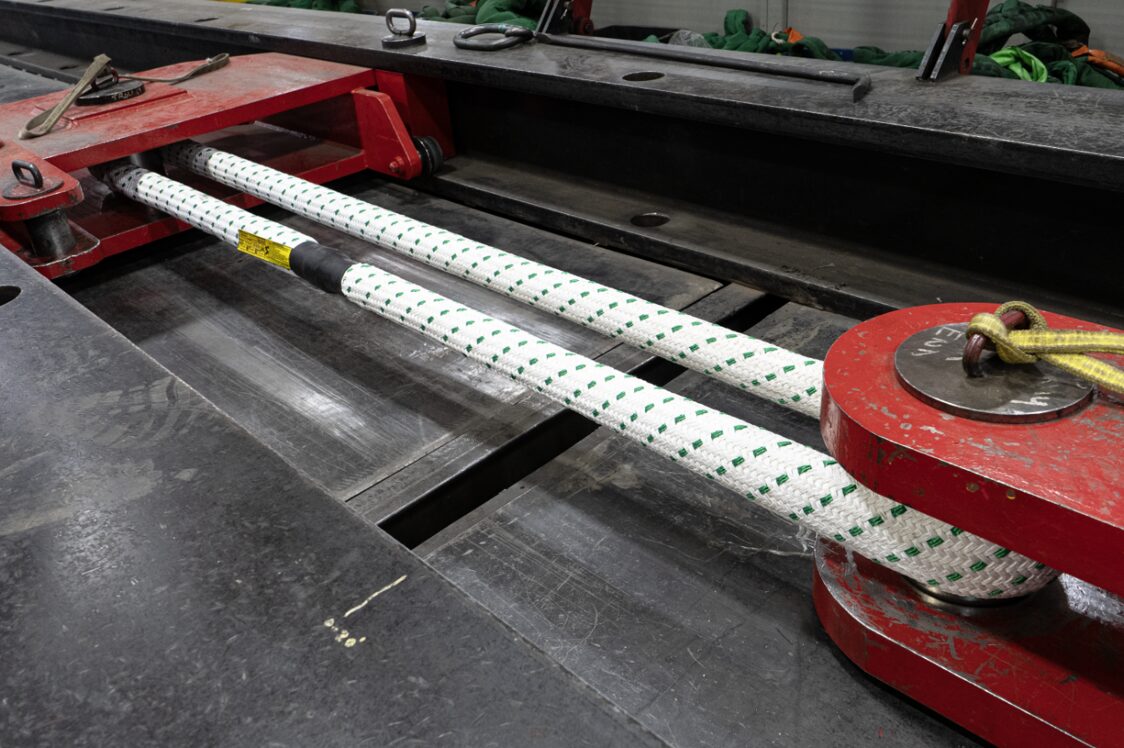

Narrow Width Profile

Helix slings offer high strength capacities while maintaining a narrow profile.

This makes Helix the ideal solution when lifting with narrow hardware or limited

space.

High Strength and Durability

Helix utilizes K-Spec core fiber, the strongest and most trusted roundsling

core yarn on the market. Refined over 30 years, K-spec is extremely durable,

strong, light weight, and has less than 1% elongation at rated capacity.

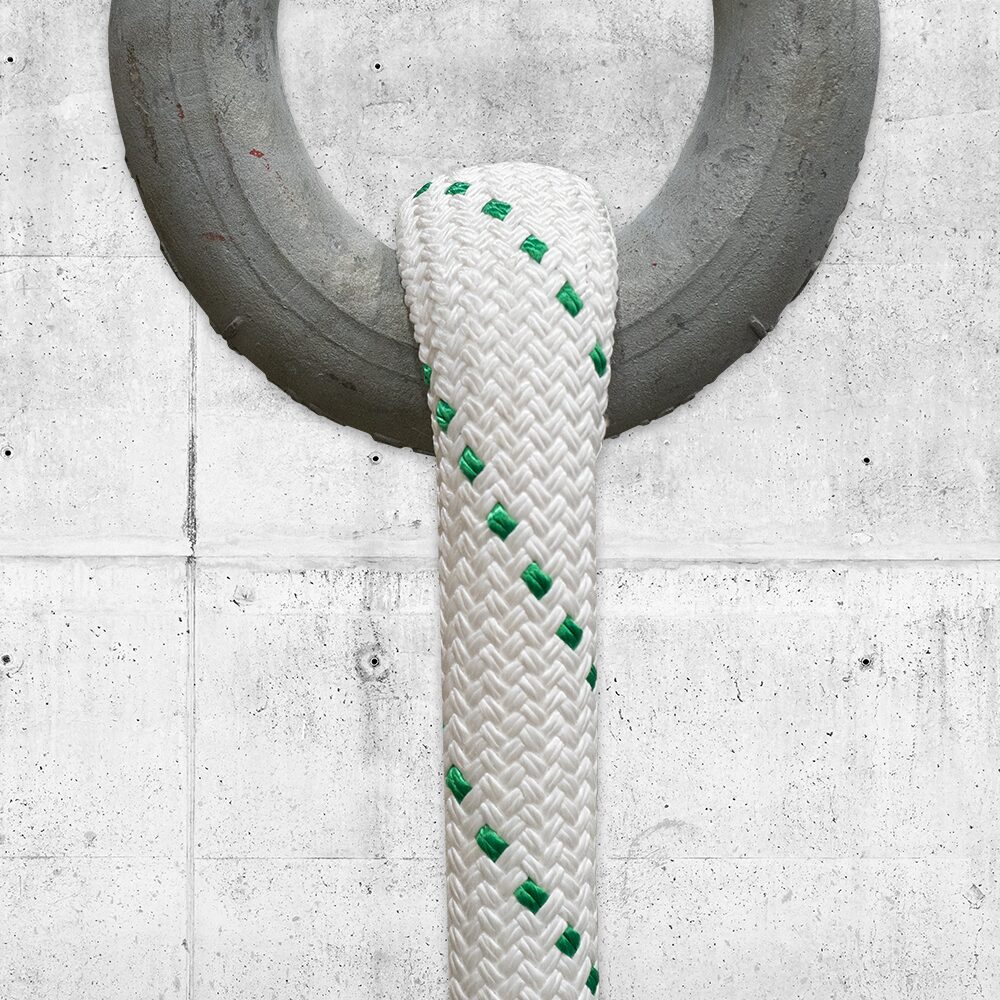

Helix Braided HMPE Sling Cover

Helix Slings are equipped with an abrasion and chemical resistant HMPE braided jacket that protects the load bearing core yarn. This jacket is braided in the USA. Rifled Cover Technology is braided directly into the HMPE Helix Jacket

increasing strength by 17% while reducing sling weight and width.

Abrasion and Cut Protection

Helix roundslings offer excellent protection against cuts and abrasion. The protective outer jackets of Helix slings are made from braided HMPE fibers. Additionally, Helix slings are completely compatible with Slingmax engineered edge and cut protection made from high-performance synthetic materials: Cornermax Pad, Cornermax Sleeve, and Spider Sleeve.

The table below is a sample representation of our Helix slings at 5:1 & 7:1 Design Factors (DF)/ Safety Factors (SF).

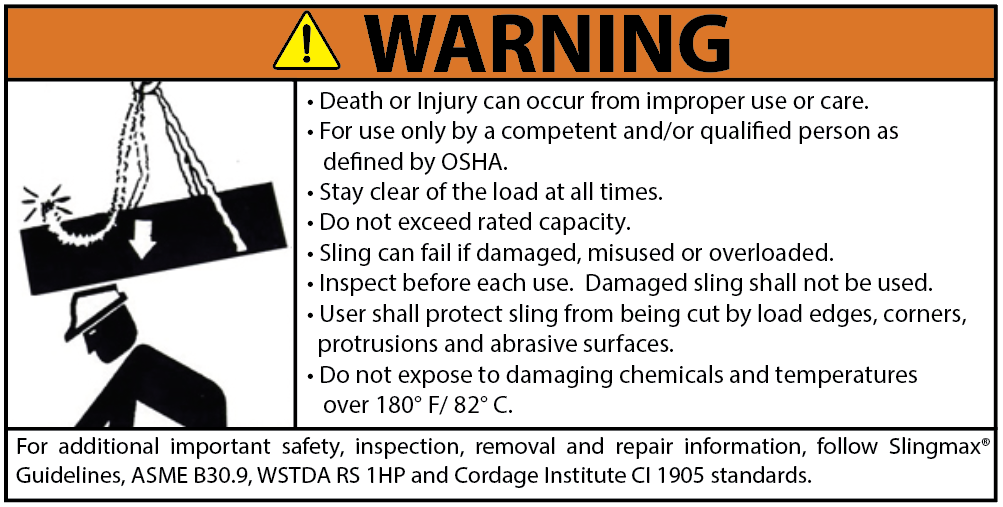

Note: Capacities shown are for one complete sling. Sling ratings based on commercial fittings of equal or greater capacity. Conforms to ANSI/ASME B30.9 chapter 6, NAVFAC P-307 section 14.7.4.3, Cordage Institute CI-1905, and Web Sling & Tie Down Association WSTDA-RS-1HP. These charts are based on 5:1 & 7:1 Design Factors (DF); but any other DF can be fabricated. Higher capacity slings are available. CAPACITIES ARE IN POUNDS (LBS) AND TONS.

English

Metric

Rigging Handbook

Fill out the form below to download a digital copy of our 2020 Rigging Handbook.

SYNTHETIC SLINGS

Slingmax has been a trusted supplier of high performance synthetic roundslings to the industrial and heavy lifting markets since 1986. Think Twin-Path® slings for all your heavy lifting and rigging needs.

RIGGING ACCESSORIES

Explore our full range of specialty rigging accessories engineered to solve complex lifting challenges, from balancing loads to testing connection points to improving on-site load control. This includes solutions like the Synthetic Equalizer Block and Pad Eye Tester.

WIRE ROPE DESIGNS

Slingmax multi-part wire rope slings are designed for increased capacity and excellent flexibility. The three-part Tri-Flex, nine-part Gator-Laid, and nine-part Gator-Flex grommet have excellent D/d ratios and can be fabricated in shorter lengths.

Need a Rigging Solution