Synthetic Slings

Twin-Path® Synthetic roundslings for heavy lifting by Slingmax® Rigging Solutions are the only synthetic roundslings available that come equipped with the Check-Fast® External Warning Indicator, Covermax® Cover, and Rifled Cover® technology. Slingmax has been a trusted supplier of high performance synthetic roundslings to the industrial and heavy lifting markets since 1986. Think Twin-Path slings for all your heavy lifting and rigging needs.

NOTE: Experts agree that over 80% of synthetic sling accidents are caused by cutting; always be SURE you have the correct Sling Protection for your specific lift!

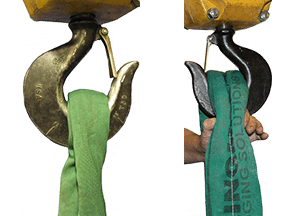

- Check-Fast Inspection System provides a pass/fail (Go/No-Go) inspection. If overloaded the External Warning Indicator disappears before the sling fails.

- The separate inner cover shows red for warning that the sling is damaged and should be taken out of service for repair.

- Twin-Path Slings are repaired with patches. Each sling is proof tested after any type of repair.

- Older slings may have two kinds of indicators. Tell-Tails warn of overload and Fiber Optics warn of core yarn damage.

Twin-Path® synthetic roundslings have Check-Fast Inspection overload indicators, Covermax Covers for superior abrasion resistance, and inner red covers as an aid to inspection. They are approximately 10% of the weight of a steel sling and are repairable.

Helix high performance fiber roundslings are narrow width heavy lift slings designed to fit in lifting hardware with limited space.Helix lifting slings utilizes K-Spec core fiber, the strongest and most trusted roundsling core yarn on the market.

Single-Path synthetic roundslings have Check-Fast Inspection overload indicators,Covermax Covers for superior abrasion resistance, and inner red covers as an aid to inspection.

The Check-Fast Inspection System is designed to improve job site safety. The Check-Fast External Warning Indicator (EWI) provides a criteria for pass/fail inspection when the internal load-bearing core yarn may be damaged. The Check-Fast Inspection System can also indicate ultraviolet (UV) light degradation, fiber-on-fiber abrasion, fatigue, and severe overload.

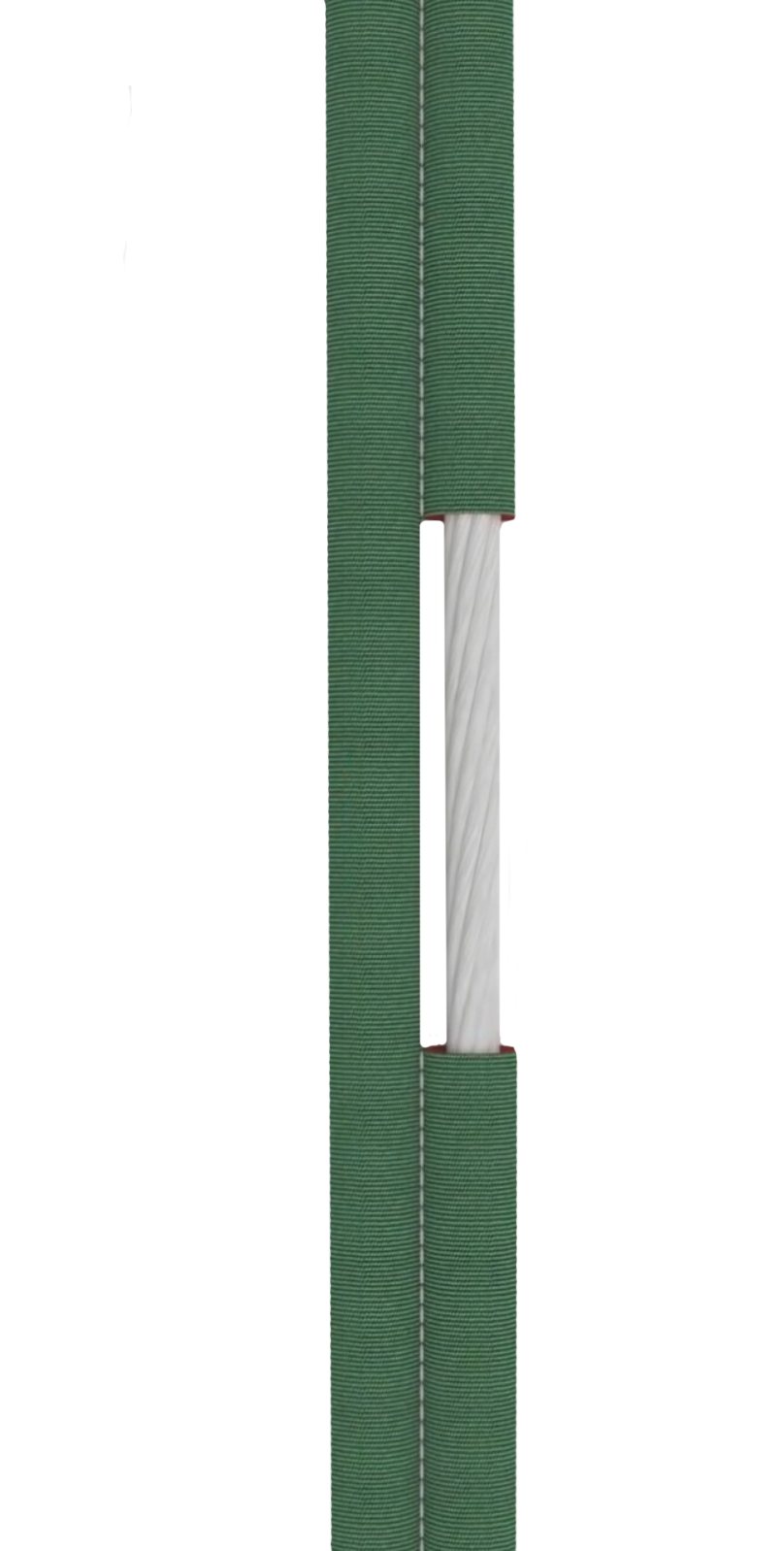

Rifled Cover Technology is a major patented breakthrough only available on Slingmax Twin-Path high-performance fiber roundslings. Rifled Cover Technology works like the inside of a rifle barrel, where the bullet spins as it leaves the muzzle of the gun. The helical winding of the core fibers significantly improves strength and efficiency.

The Twin-Path Adjustable Bridle (TPXA with K-Spec fiber core yarn or TPA with polyester core yarn) is a two-leg bridle made with a Twin-Path roundsling and adjustable bridle ring. When tension is applied to the Twin-Path Adjustable Bridle, it self-adjusts until the lifting point is over the center of gravity (COG). This allows the two legs to be adjusted for a level lift without the need for custom slings or hardware.

The Sparkeater sling (SE) is the sling to use when the job site is in a hot environment (up to 300°F or 150°C). These slings are made with high-temperature core yarns and a high temperature cover.

The Twin-Path Field Taper is a removable, repositionable wrap that reduces the width of TPXCF slings onsite. This is a tool that can be utilized to fit a sling into smaller openings without sacrificing sling capacity.

Rigging Handbook

Fill out the form below to download a digital copy of our 2020 Rigging Handbook.

SYNTHETIC SLINGS

Slingmax has been a trusted supplier of high performance synthetic roundslings to the industrial and heavy lifting markets since 1986. Think Twin-Path® slings for all your heavy lifting and rigging needs.

RIGGING ACCESSORIES

The Equalizer Block is used to maintain tension on all legs of the sling during a lift. The Equalizer Block will automatically adjust itself when tension is put on the device from the sling. This was designed specifically for Twin-Path® Extra Slings.

WIRE ROPE DESIGNS

Slingmax multi-part wire rope slings are designed for increased capacity and excellent flexibility. The three-part Tri-Flex, nine-part Gator-Laid, and nine-part Gator-Flex grommet have excellent D/d ratios and can be fabricated in shorter lengths.

Need a Rigging Solution