Cut Protection

CornerMax® Pads

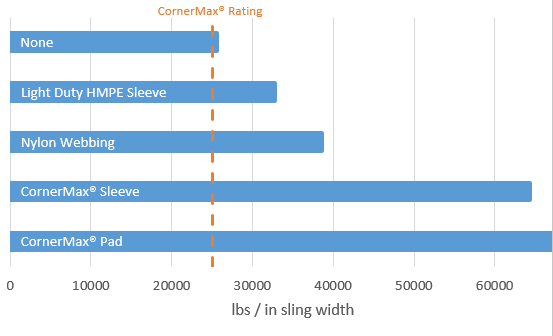

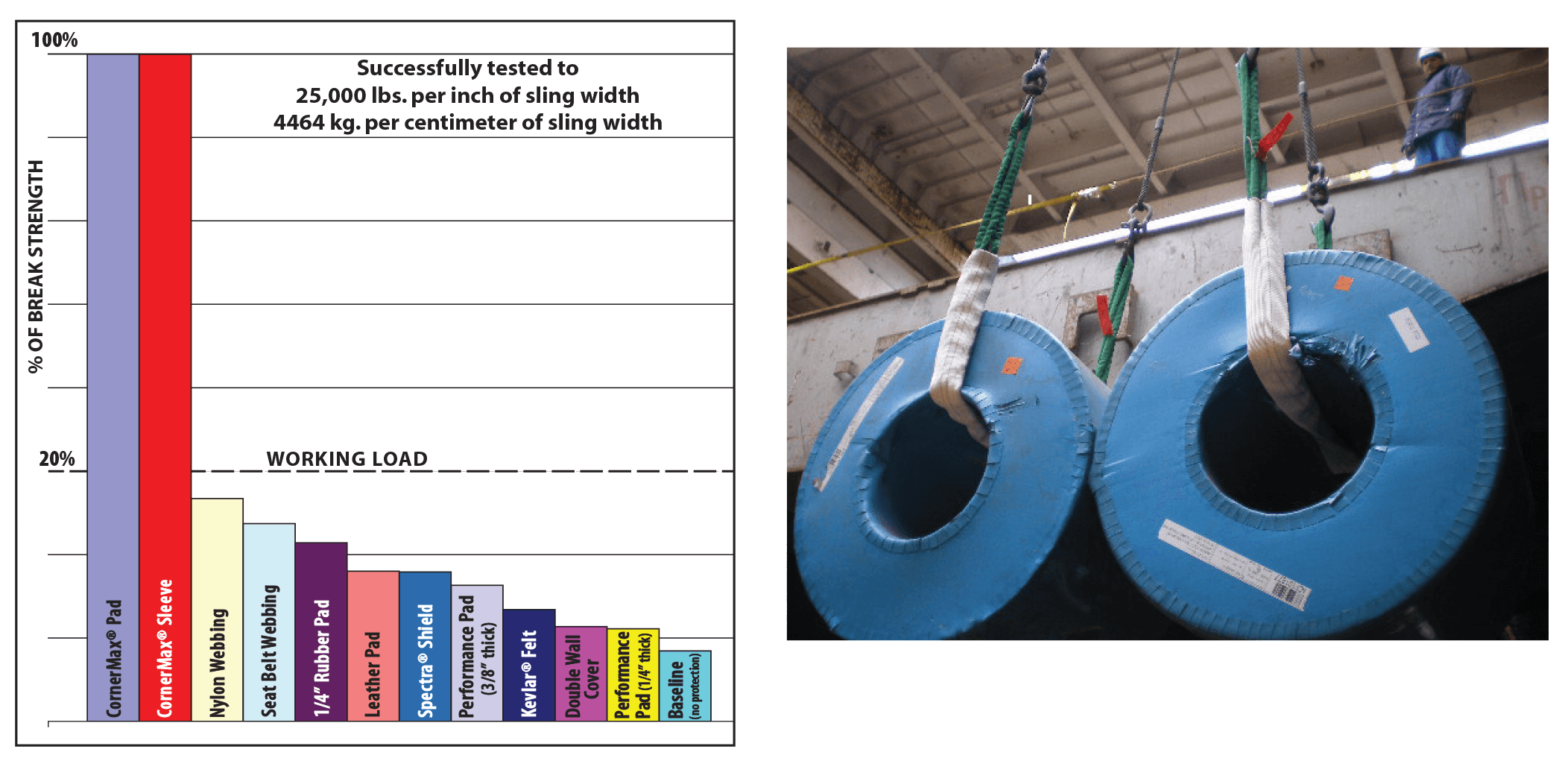

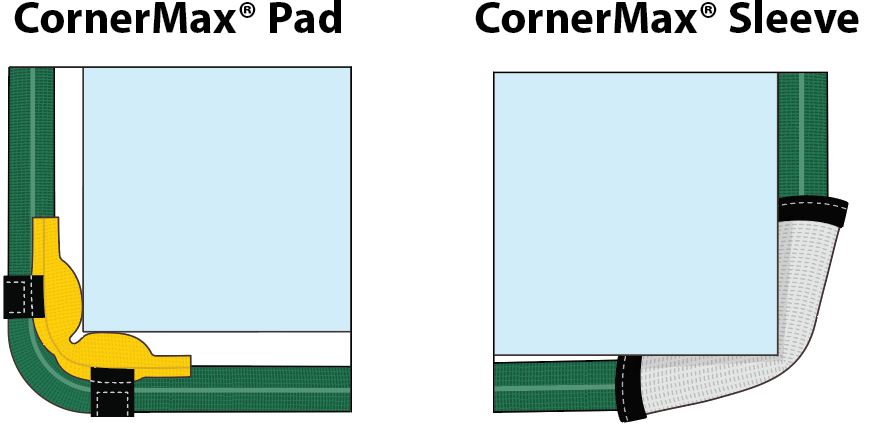

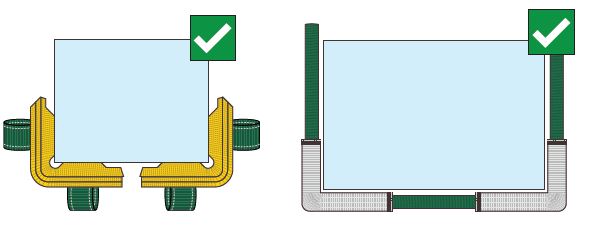

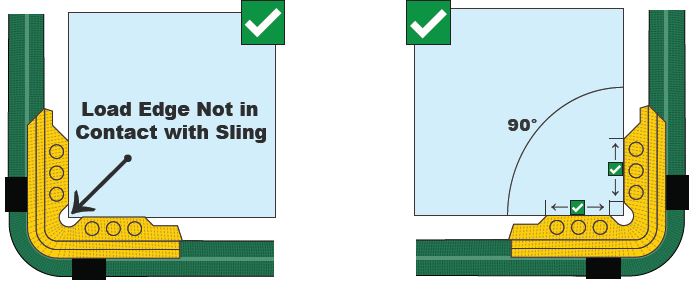

CornerMax Pads are one of the engineered cut protection options developed by Slingmax® Rigging Solutions. The CornerMax Pad is designed to be used on loads that have a 90-degree straight edge. The pad creates a “tunnel” of cut protection known as the “no-touch zone”. The edge of the load does not come in contact with the pad or sling, thus protecting the sling. Note that the sides of the load must completely support the pads in order to create and maintain the “tunnel”. CornerMax Pads have a rated working load limit of 25,000 pounds per inch (4464kg per cm) of sling width.

|

CornerMax® Part No.

|

Sling Width (inches)

|

CornerMax®

Approx. Width (inches)

|

CornerMax®

Approx. Wt. (lbs)

|

|---|---|---|---|

|

CRNMX02

|

1 & 2 | 4 | 1.00 |

|

CRNMX03

|

3 | 5 | 1.25 |

|

CRNMX04

|

4 | 6 | 1.50 |

|

CRNMX05

|

5 | 8 | 2.00 |

|

CRNMX06

|

6 | 8 | 2.00 |

|

CRNMX08

|

8 | 10 | 2.50 |

|

CRNMX10

|

10 | 12 | 3.00 |

|

CRNMX12

|

12 | 16 | 5.50 |

|

CRNMX14

|

14 | 18 | 6.50 |

| NOTE: All CornerMax® pads are approximately 9 inches in length unless otherwise specified. | |||

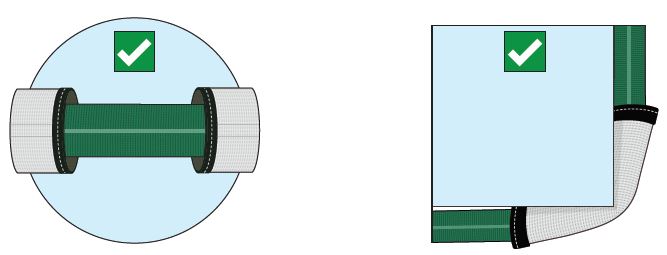

CornerMax® Sleeve

The CornerMax Sleeve is the ideal solution to protect synthetic slings from cutting when it is not practical to use a CornerMax® Pad. This can be due to the geometry of the load edge not allowing space for a pad or repetitive uses, such as unloading steel coils. The extreme cut resistance of the sleeve is attributed to its proprietary weave design and is unmatched in the rigging industry with a cut protection rating of 25,000 pounds (4464kg per cm) per inch of sling width. The CornerMax Sleeve is made with high-tech fiber and is laboratory tested for cut resistance. In some applications, the CornerMax Sleeve may be attached to the sling to prevent sliding of the pad between lifts. The true benefits of the revolutionary material far outweigh the costs and now provide for the use of synthetic slings in applications previously dominated by heavy chain, mesh, and wire rope slings.

|

CornerMax® Sleeve Part No.

|

Approx. Weight Per Foot (lbs.)

|

Approx. Internal Sleeve Width (inches)

|

Approx. External Sleeve Width. (inches)

|

|---|---|---|---|

|

CRNMXS03

|

.57 | 4 | 5 |

|

CRNMXS04

|

.66 | 5 | 6 |

|

CRNMXS08

|

.97 | 8 | 9 |

|

CRNMXS10

|

1.19 | 10 | 11 |

Cut Protection Use & Care

BEFORE EACH USE

DEATH or INJURY can occur from improper use or care

1. SLING USERS SHALL BE TRAINED Do not use this pad or sleeve unless you are

properly trained.

2. Read and follow all instructions and warnings in this manual.

3. CornerMax® pads and sleeves are rated for 25,000 lbs per inch of sling width.

No material is cut proof. Check tag on pad or sleeve to confirm that the pad is

adequately rated for the load.

4. Inspect pads or sleeve for damage before each use including:

- Missing or unreadable identification tag

- Holes, tears, cuts, abrasive wear or snags

- Broken stitching or seams

- Acid or caustic burns

- Weld splatter or heat damage

- Any other condition, including visible damage, that causes doubt as to

the continued use of the pad

IF ANY OF THESE CONDITIONS ARE DETECTED – REMOVE FROM SERVICE

IMMEDIATELY.

NEVER USE A DAMAGED PAD OR SLEEVE. A DAMAGED PAD OR SLEEVE MAY

NOT PROTECT THE SLING AND LEAD TO FAILURE.

INSPECTION FREQUENCIES

1. All slings and rigging shall be inspected before each use.

2. Documented periodic inspections of the pad or sleeve shall be completed at

least annually or more frequently depending on service.

- Refer to ASME B30.9 and / or contact manufacturer for

recommendations for guidance on service intervals.

USE

1. Select the appropriate sling and rigging. Only use CornerMax Sleeves and Pads with synthetic slings.

DO NOT USE WITH WIRE ROPE OR CHAIN SLINGS. USE WITH OTHER TYPES OF RIGGING IS PROHIBITED AND CAN LEAD TO FAILURE OF THE SLEEVE/PAD AND/OR RIGGING.

- Refer to manuals and instructions of selected rigging for proper use.

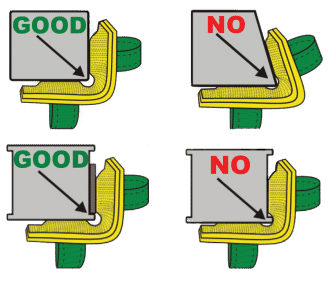

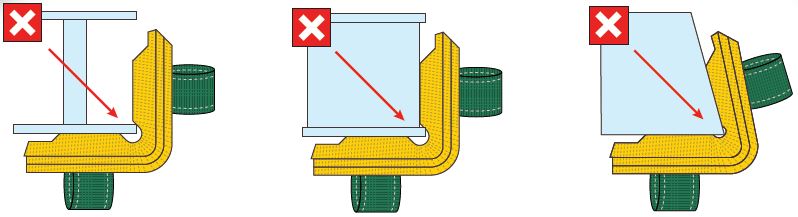

2. Position the pads correctly on the load.

ENSURE PADS AND SLEEVES MAKE CONTACT WITH TWO LOAD EDGES.

3. CornerMax Pad must be used in pairs.

4. CornerMax Pads must be used at a 90°-degree angle and make full contact on both sides to create a separation between the edge of the load and the sling.

Do not allow load edge to make contact with the CornerMax Pad.

5. CornerMax Sleeves are versatile and can be used on any angled edge or surface.

To ensure full contact do not use CornerMax Pads on curved surfaces. Use Cornermax Sleeve Instead.

-

- Ensure sling is not too wide for the pad being used to avoid sling from contacting edge.

- To prevent sling damage ensure all edges are protected. This can include edges at the top of the object being lifted.

- Materials that are hardened or have a Rockwell C hardness above 35 may reduce effective protection for the CornerMax Sleeve. Consult Slingmax before using above this hardness.

- To prevent damage to the pad, sleeve, and/or sling do not expose to chemicals and/or temperatures above 180°F/82°C.

6. Apply the load carefully and slowly, ensuring the sling and pads and/or sleeves are oriented correctly. You may need to perform this several times to ensure the CornerMax Pad and Sleeve are not being damaged.

- Keep hands clear when the sling is being tightened.

- To prevent cutting do not allow the sling, pads or sleeves to slide across edges while under load.

BE CAREFUL WHILE USING HIGH STRETCH SLINGS, SUCH AS NYLON OR POLYESTER, BECAUSE THEY ARE MORE SUSCEPTIBLE TO CUTTING.

- Stay clear of load at all times!

STOP THE LIFT IMMEDIATELY IF THE LOAD DOES NOT LIFT EVENLY, THE PADS AND / OR SLEEVES SHIFT, OR ANY OTHER OBSERVED FAILURE OF THE RIGGING IS DETECTED.

CARE

When storing CornerMax Pads and Sleeves prevent contact with possible mechanical damage, corrosion, dust, grit or extreme temperatures. To clean: use mild soap and water and allow to air dry before storing. Do not machine wash or dry, to avoid damaging the pad or sleeve.

REPAIR

CornerMax Pads and Sleeves cannot be repaired. Immediately dispose of damaged pads and sleeves.

DISPOSAL

Before disposing of CornerMax Pads and Sleeves, they shall be marked of destroyed to prevent inadvertent use. Waste shall be disposed of in accordance with national and local regulations.

TRAINING & RESOURCES

Per ASME B30.9 & OSHA Sling users shall be trained. Qualifying persons performing rigging functions shall meet the applicable criteria and shall, through education, training, experience, skill, and physical ability, as necessary, be competent and capable to perform the job. Rigging training is widely available through your local Slingmax Dealer.

For training information please contact your local Slingmax Dealer or visit www.slingmax.com

ASSOCIATIONS

For additional information on the safe use, inspection, and training requirements, please consult the standards and reference items below:

• WSTDA-RS-1HP

• ASME B30.9

• CI 1905

• OSHA 29 CFR, 1910.184

• Slingmax Smartphone App

Rigging Handbook

Fill out the form below to download a digital copy of our 2020 Rigging Handbook.

SYNTHETIC SLINGS

Slingmax has been a trusted supplier of high performance synthetic roundslings to the industrial and heavy lifting markets since 1986. Think Twin-Path® slings for all your heavy lifting and rigging needs.

RIGGING ACCESSORIES

Explore our full range of specialty rigging accessories engineered to solve complex lifting challenges, from balancing loads to testing connection points to improving on-site load control. This includes solutions like the Synthetic Equalizer Block and Pad Eye Tester.

WIRE ROPE DESIGNS

Slingmax multi-part wire rope slings are designed for increased capacity and excellent flexibility. The three-part Tri-Flex, nine-part Gator-Laid, and nine-part Gator-Flex grommet have excellent D/d ratios and can be fabricated in shorter lengths.

Need a Rigging Solution