Twin-Path® Heavy Lift Slings

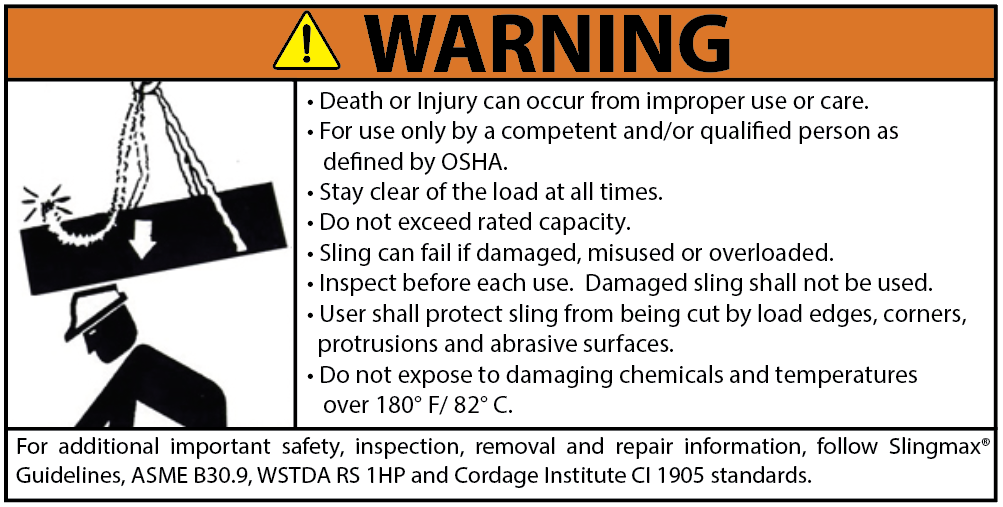

Perform heavy lifts with Twin-Path high-performance synthetic roundslings. Twin-Path slings are used worldwide in place of steel rigging for heavy lifts. They are approximately 10% of the weight of a steel sling and are repairable. The Twin-Path sling design, which has two individual paths of fiber working as one sling, gives the rigger confidence. Additionally, these slings designed for heavy lifting come equipped with Check-Fast® Inspection overload indicators, Covermax® Covers for superior abrasion resistance, and inner red covers as an aid to inspection. These slings have less than 1% elongation at rated capacity. They are also protected by an abrasion- and chemical-resistant jacket constructed from industrial nylon and HMPE fibers, which enhances burst strength and prevents rupture under extreme tension.

If productivity, safety, and precision are important, then Twin-Path high-performance roundslings are your best choice for all industrial heavy lifting applications. Independent testing shows that K-Spec® Core Yarn (approved by DNV) is the longest lasting load-bearing core yarn in any sling.

Advantages of Twin-Path Slings

Lightweight and Ergonomic

One of the biggest advantages of Twin-Path slings is their lightweight and ergonomic design. They are much easier to handle and rig than heavy steel slings, making them a safer choice for workers and reducing the risk of injuries.

High Strength and Durability

Despite being lightweight, Twin-Path slings are incredibly strong and durable. Inside every Twin-Path roundsling are load bearing core yarns called K-Spec, which is 10 times the strength of steel.

This high strength makes these slings suitable for a wide range of applications, from construction and power generation to wind energy and offshore oil and gas.

Easy Inspection and Repair

Twin-Path High Performance Roundslings are equipped with the Check-Fast Inspection System which acts as an external warning indicator (EWI) that sticks out from the cover and if overloaded, retracts back into the cover and disappears. The core yarns of every Twin Path sling is protected by our Covermax Cover, which is a double layered jacket that is very abrasion resistant and includes contrasting colors on the external and internal layers for easy damage identification. Due to the Twin-Path design, abrasion damage can be easily repaired by any authorized Slingmax manufacturer. This ensures that the sling remains in good condition and can be used safely and efficiently for many lifts.

Abrasion and Cut Protection

Twin-Path slings come equipped with a Covermax Cover that has excellent protection against abrasion and cuts. This outer jacket is made from two layers of heavy-duty industrial nylon, providing excellent UV protection and abrasion resistance. It offers enhanced cut, wear, and burst resistance while maintaining flexibility for demanding lifting applications.

Additionally, Slingmax offers three types of engineered edge and cut protection made from high-performance synthetic materials: Cornermax Pad, Cornermax Sleeve, and Synthetic Armor Pad.

Enhanced HMPE Covermax Cover

Twin-Path slings that are 6" or wider feature an outer jacket woven with durable HMPE fibers, designed to enhance toughness and longevity. These high-performance fibers provide exceptional resistance to water and chemicals, significantly extending the sling’s lifespan.

When under extreme tension near the working load limit, the jacket helps prevent rupture or bursting, ensuring added safety. With a 10% higher burst strength than previous top-performing materials and exceeding industry minimums by 54%, this new enhanced covermax cover sets a new standard for durability and reliability.

Twin-Path Sling Design and Applications

Slingmax® Twin-Path roundslings are a type of high performance, endless round sling that are constructed from two individual paths of internal load-bearing high performance fibers and two layers of external covers that all work together as one sling. Due to their strength, durability, and flexibility, Twin-Path slings are commonly used in a range of industries that require overhead lifting such as:

Construction

Used in a wide variety of applications and types of construction projects, Twin-Path slings are the preferred lifting sling for projects like building bridges or constructing skyscrapers. Lightweight and repairable, Twin-Path slings are designed to be easy to rig and long lasting.

Power Generation and Distribution

Installation and maintenance of power generation equipment made easy with Twin-Path round slings. Our slings have been lifting power components such as turbines and generators for over 30 years!

Wind Energy

Twin-Path slings are used for the installation and maintenance of onshore and offshore wind turbines, including the setting of towers and lifting of nacelles.

Offshore Oil and Gas

Neutrally buoyant and unaffected by long exposure to seawater, Twin-Path slings are used extensively during the installation and maintenance of offshore oil and gas production equipment, such as pumps or large engines.

Manufacturing and General Industry

Twin-Path slings are used for a wide range of manufacturing and general industry applications, particularly for die lifts and other repetitive lifts where abrasion damage and tension fatigue could be a concern.

The table below is a sample representation of our Twin-Path® slings at a 5:1 Design Factor (DF)/ Safety Factor (SF). Capacities up to 4000 Te MBL and other DF/SF Twin-Path products are available. Please call, email, or utilize our "Contact Us" form for special requests.

English

Metric

Rigging Handbook

Fill out the form below to download a digital copy of our 2020 Rigging Handbook.

SYNTHETIC SLINGS

Slingmax has been a trusted supplier of high performance synthetic roundslings to the industrial and heavy lifting markets since 1986. Think Twin-Path® slings for all your heavy lifting and rigging needs.

RIGGING ACCESSORIES

Explore our full range of specialty rigging accessories engineered to solve complex lifting challenges, from balancing loads to testing connection points to improving on-site load control. This includes solutions like the Synthetic Equalizer Block and Pad Eye Tester.

WIRE ROPE DESIGNS

Slingmax multi-part wire rope slings are designed for increased capacity and excellent flexibility. The three-part Tri-Flex, nine-part Gator-Laid, and nine-part Gator-Flex grommet have excellent D/d ratios and can be fabricated in shorter lengths.

Need a Rigging Solution